A thing Cum Passenger Lift is an important part of any building with more than one floor because it makes moving things and people easier. Our service elevator is made to meet the needs of both people and businesses, which makes it a flexible choice for a range of building types. Moving goods and people to different floors is quick and easy with the lift, which needs little upkeep and downtime.

The price of the service lift is reasonable, and it can be changed to fit the needs of each client. Modern technology and high-quality materials were used to make our goods passenger lift, which means it will last for a long time and be reliable. We also have electric lifts for people and goods, which is good for the environment and saves money.

Traditional hydraulic lifts use more energy than the electric passenger and service lifts, but it is safer, smoother and quieter. Our goods and passenger lift also has high-tech safety features that keep both people and things as safe as possible. It is easy for the goods man lift and goods man lift to move heavy things around in industrial areas.

Getting to different floors of a building is easy with the industrial man lift, which is a good way to move things and people around in industrial settings. The price of our services lifts is low so that it can be used by both businesses and people without breaking the bank. The price of the service lift is reasonable, and it can be changed to fit the needs of each client.

Finally, our Goods Cum Passenger Lift is the best choice if you want a safe and affordable way to lift people in large buildings. Get in touch with us right away to find out more about our service elevator and service lift options and to get a price for your building.

• A digital car position indicator makes it clear where the cabin is on every floor.

• The UP/DN indicator showed which way the cabin was going.

• Protect against voltage: You can set an upper and lower limit for each phase (220V) instead of the combined three-phase (440 V). This means the most safety.

• You can set the ampere level for each phase to ensure safety against over- and under-load.

• Phase Preventer saves electrical parts when either the single phase or the two phase power goes out.

• The Phase Sequence Corrector/Auto Phase Changer sorts out the phase polarity automatically when the phase in the source changes.

• MFFS (Magnet Floor and Final Sensing with the help of a REED sensor) is the newest version of the old limit switch technology. Reed sensors don't need to be touched to work, but their life is very long because they use detecting technology. Also, the correctness of the same can't be beat.

• A special M.C.B. was made for Rachna Elevator & Cranes to make sure there is ultimate safety in case the panel stops working.

• There is a buffer in the pit to protect the house from damage.

• Doors that fold up.

• Widest opening after the bunch.

• There is an emergency stop button on every floor that can be used to stop the ship in an emergency.

• Mechanical and electrical door lock:

• The Over Speed Governor stops the lift if the cabin falls free, which is done by using mechanical brakes or safety dogs. There is a counterweight with this.

•With Counter Weight and Hydraulic Type, you get the following:

• ARD stands for "Auto Rescue Device." This device is used to free people who are stuck in lifts because of an emergency, a breakdown, insufficient power, or maintenance. After getting off at the nearest floor, it opens the door

Rachna Elevator & Cranes, a renowned company, specializes in top-quality Freight Cum Passenger Elevator in Bhimunipatnam. With their expertise and dedication to excellence, they offer reliable Freight Cum Passenger Elevator solutions for various industrial needs in the region.

The Freight Cum Passenger Elevator is design For industrial use. We are the best manufacturers of Freight Cum Passenger Elevator Manufacturers in Bhimunipatnam.

Besides these Freight Cum Passenger Elevator, we also provide Freight Cum Passenger Elevator at reasonable prices and optimum quality.

When the need to incorporate an overhead industria system is eliminated, then the gantry Freight Cum Passenger Elevator is used and it comes into existence. Further, this Freight Cum Passenger Elevator does not need to be attached to a rigid support. We are the best Heavy Duty Freight Cum Passenger Elevator Manufacturers, Suppliers and Exporters in Bhimunipatnam.

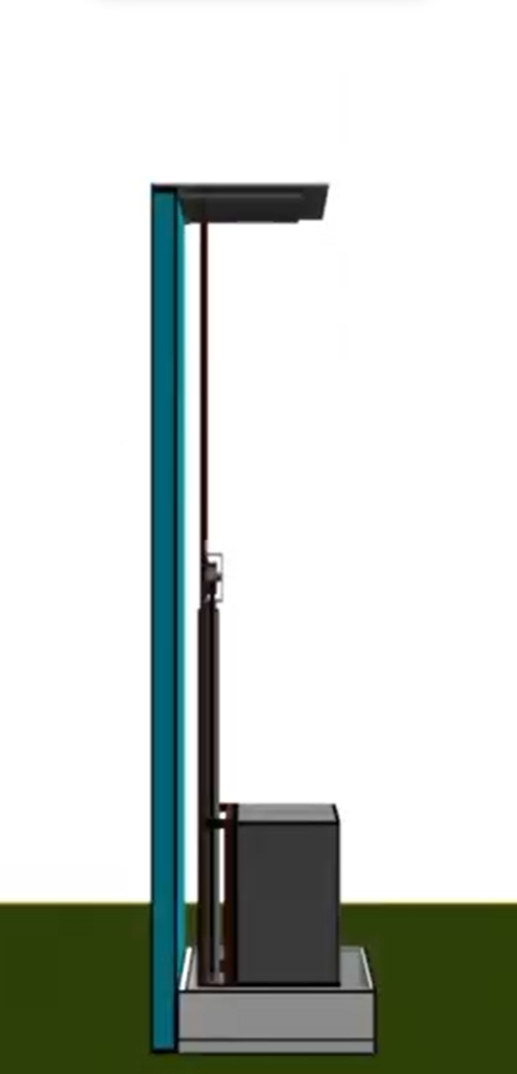

Hydraulic Freight Cum Passenger Elevator Hole Less Type is safest technology. It works in such a manner when oil push in the cylinder with the help of power pack piston moves up which rise the cabin. On another side by just releasing the wall oil from the cylinder come back in the power pack which lower down the cabin. In this system cylinder installs on the parallel of the wall. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

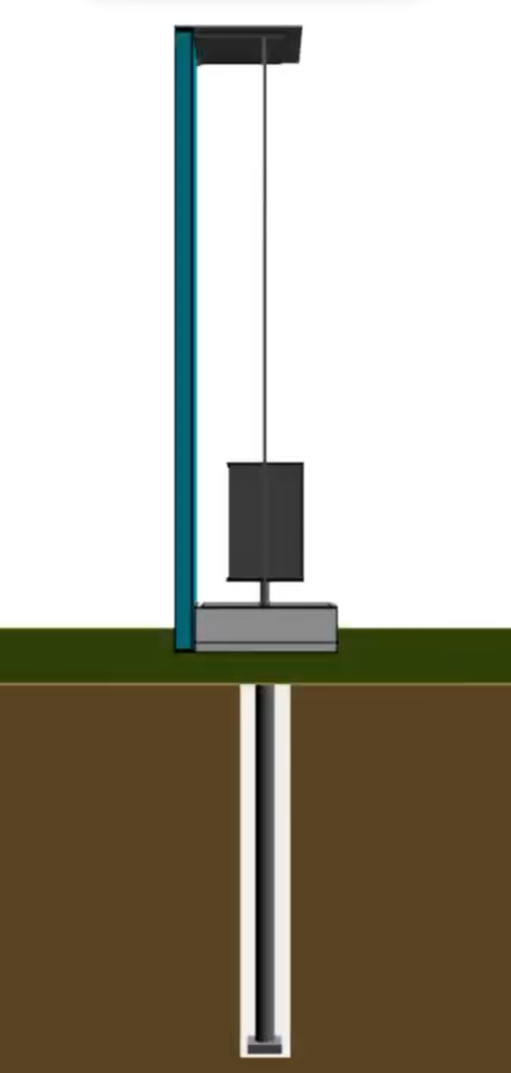

Hydraulic Freight Cum Passenger Elevator Hole Type is safest technology. It works in such a manner when oil push in the cylinder with the help of power pack piston moves up which rise the cabin. On another side by just releasing the wall oil from the cylinder come back in the power pack which lower down the cabin. In this system a hole is drilled in the pit where cylinder is to be install. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

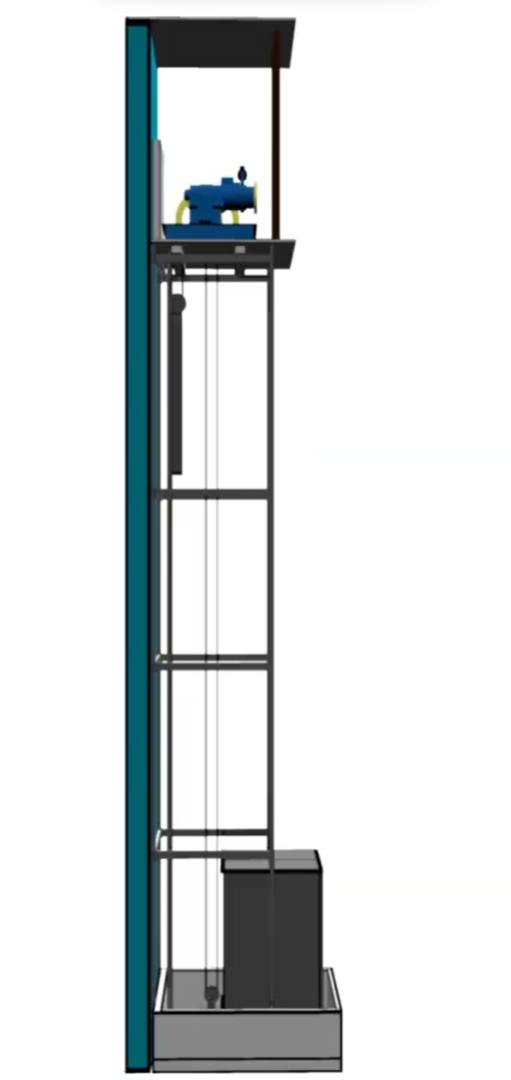

Freight Cum Passenger Elevator Counter Weight Type Without Machine Room MRL is bit expensive. In this type Geared traction machine is used in which motor is coupled to a worm which transmit the motion to the pulley / sheave through worm gear. Sheave moves the wire rope in too & fro motion who’s one end tie with the cabin & other tie with the counter weight. In this system machine is installed in the in the shaft on I-BEAM instead of machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

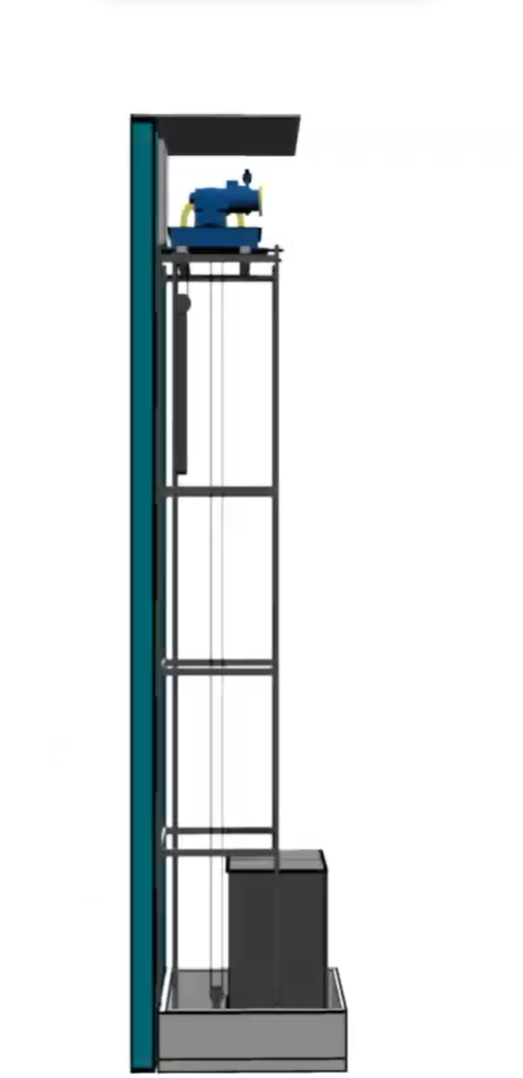

Freight Cum Passenger Elevator Counter Weight Type With Machine Room is bit expensive. In this type Geared traction machine is used in which motor is coupled to a worm which transmit the motion to the pulley / sheave through worm gear. Sheave moves the wire rope in too & fro motion who’s one end tie with the cabin & other tie with the counter weight. In this system machine is installed in the machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING