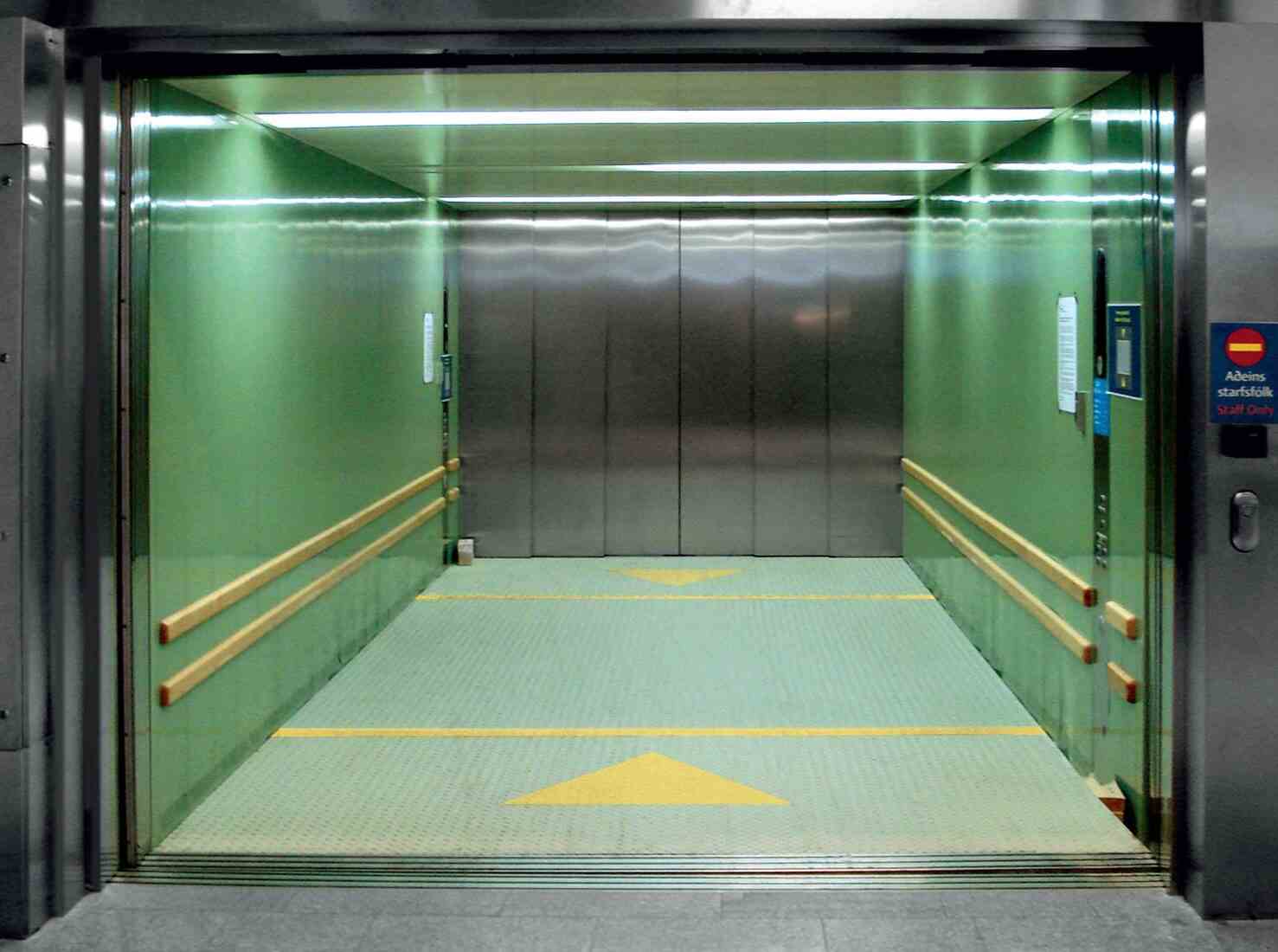

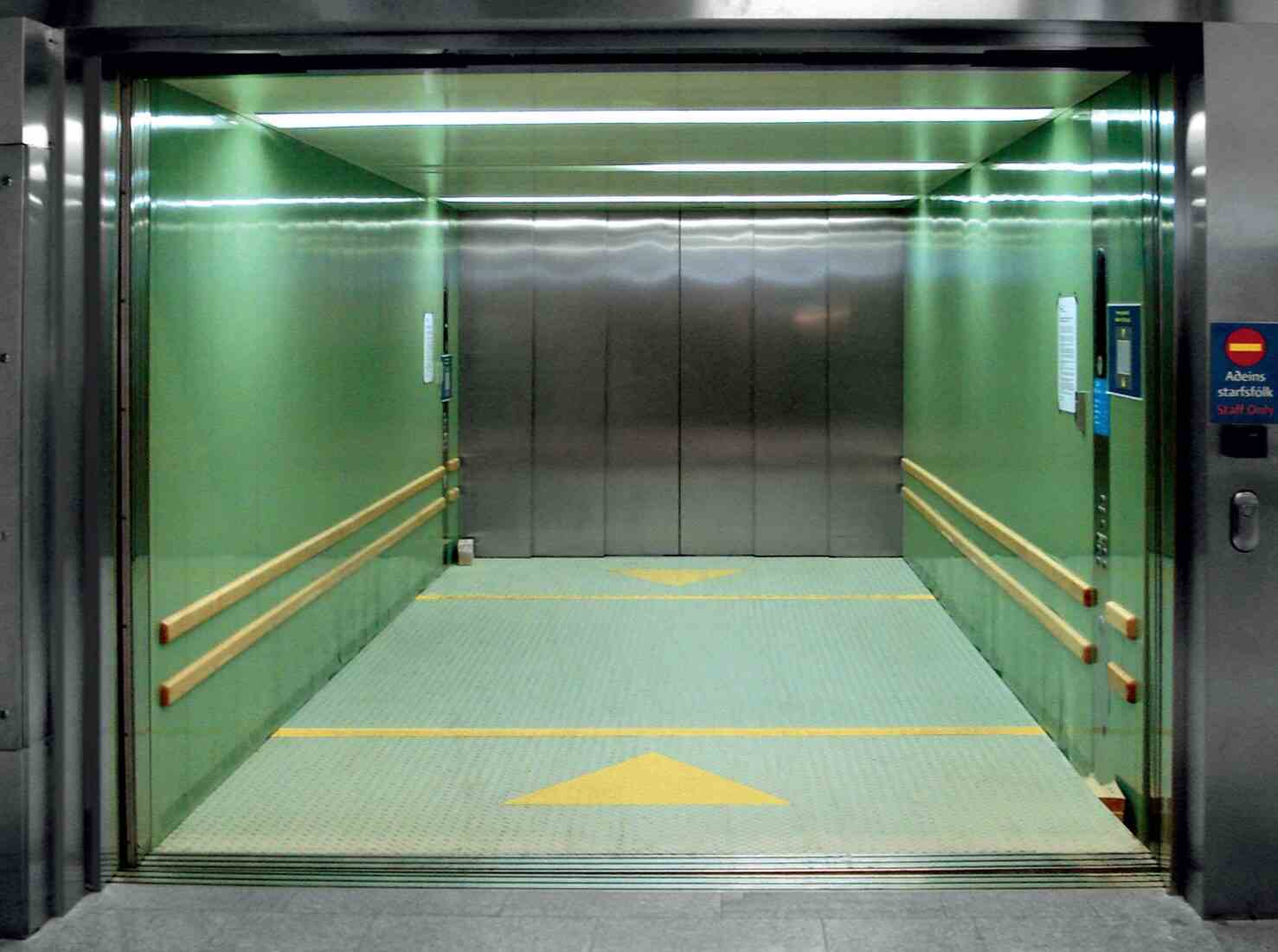

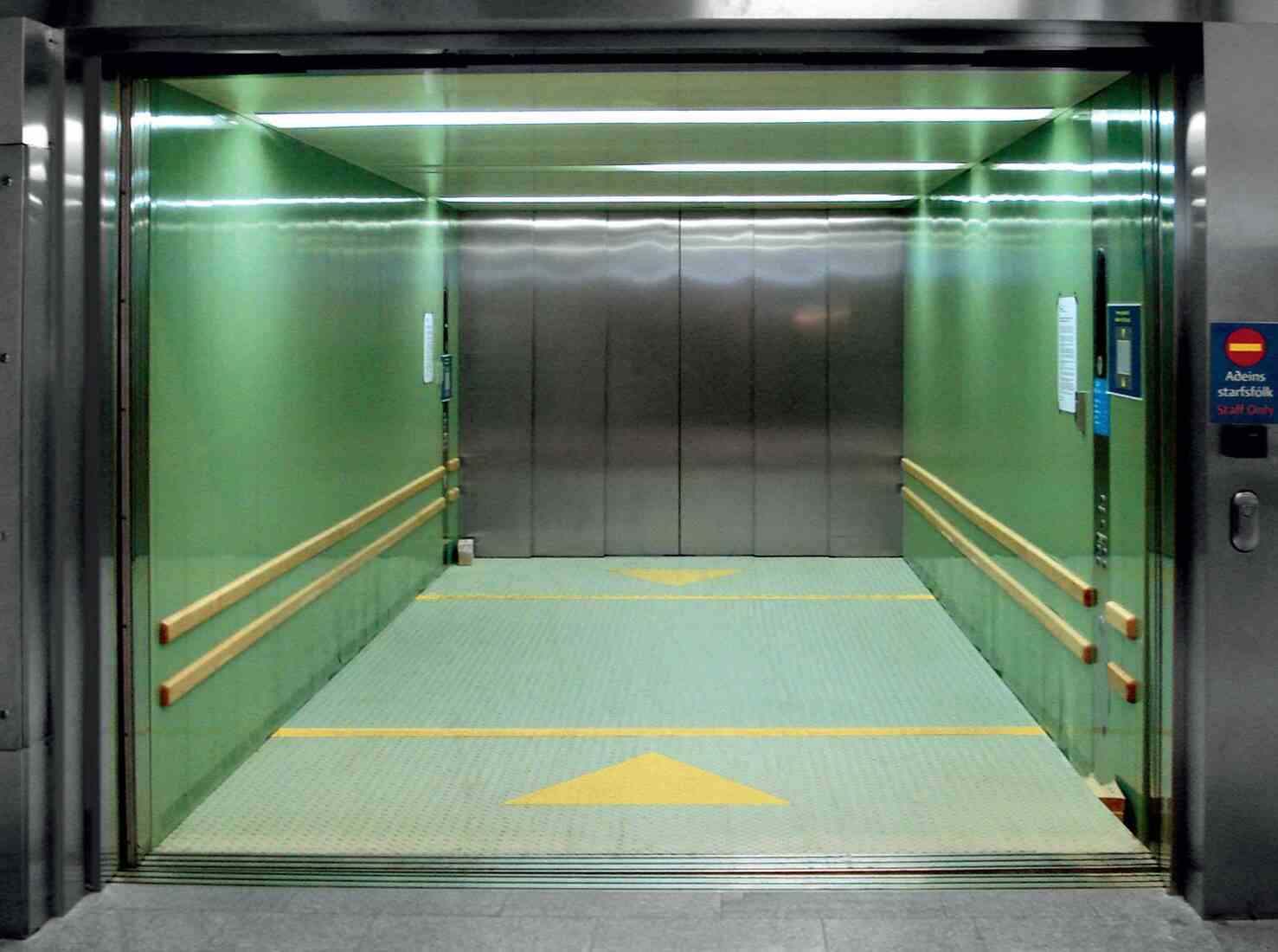

A goods lift, sometimes called an industrial lift, is a type of lift that moves items, packages and goods within a building or from one floor to another. They can carry heavy loads and are usually bigger and stronger than passenger lifts. In business and factory buildings, like warehouses and workshops, they are often used.

In any business or factory where moving things around is important, an industrial goods lift is an important part of the building. The lift's purpose is to make moving things around inside the building easy and convenient. Our company, [Rachna Elevator & Cranes], has been making high-quality goods lifts for many years and is one of the best in Delhi. We offer a variety of goods lifts, such as hydraulic goods lifts, electric goods lifts, and industrial lifts. Each type is made to meet specific needs.

Having an industrial lift is important for any business that moves materials and goods. Our office lifts are made to meet the needs of today's businesses and come with the newest technology to make sure they are as safe and effective as possible. We have many types of industrial lifts, such as electric goods lifts, hydraulic goods lift, and cargo lifts.

Hydraulic goods lifts are great for moving heavy loads because they are driven by hydraulic pressure. Our hydraulic goods lifts are made to work quickly and reliably, which makes moving things around a breeze. There are many kinds of hydraulic goods lifts that we sell, such as platform lifts and wall-mounted lifts. Each one is made to meet specific needs.

In any workplace setting where moving things around is important, a goods elevator is a must-have. Our industrial lifts are made to meet the needs of today's businesses and come with the newest technology to make sure they are as safe and effective as possible. Industrial lifts like hydraulic lifts, electric lifts and loft goods lifts are all the kinds of lifts we sell.

Getting a goods lift for your home can make your life easier by making moving things around your house easier. Different types of home goods lifts are available, such as hydraulic lifts, electric lifts, and wall mounted goods lift. Each type is made to meet specific needs.

electric goods lift are great for moving lighter loads because they are powered by electricity. Our electric goods lifts are made to work quickly and reliably, which makes moving things around a breeze. There are many kinds of electric goods lifts that we sell, such as platform lifts and wall-mounted lifts. Each one is made to meet specific needs.

Our goal at Rachna Elevator & Cranes is to give our customers the best lift options possible. There are hydraulic goods lifts, electric goods lifts, business lifts, goods lift for warehouse, industrial lifts and more in our line of goods. We have a group of professionals whose only goal is to give you the best customer service and help. Get in touch with us right away to find the best lift for your needs.

• A digital car position indicator makes it clear where the cabin is on every floor.

• The UP/DN indicator showed which way the cabin was going.

• Protect against voltage: You can set an upper and lower limit for each phase (220V) instead Of the combined three-phase (440 V). This means the most safety.

• You can set the ampere level for each phase to ensure safety against over- and under-load.

• Phase Preventer saves electrical parts when either the single phase or the two phase power goes out.

• The Phase Sequence Corrector/Auto Phase Changer sorts out the phase polarity automatically when the phase in the source changes.

• MFFS (Magnet Floor and Final Sensing with the help of a REED sensor) is the newest version of the old limit switch technology. Reed sensors don't need to be touched to work, but their life is very long because they use detecting technology. Also, the correctness of the same can't be beat.

• A special M.C.B. was made for Rachna Elevator & Cranes to make sure there is ultimate safety in case the panel stops working.

• There is a buffer in the pit to protect the house from damage.

• Doors that fold up.

• Widest opening after the bunch.

• There is an emergency stop button on every floor that can be used to stop the ship in an emergency.

The electrical mechanical door lock means that the door won't open while the lift is moving, and it will only open on the floor where the cabin lands. The lift will not move until all of the gates are closed.

• The Over Speed Governor Stops the lift if the cabin falls free, which is done by using mechanical brakes or safety dogs. There is a counterweight with this.

• A digital car position indicator makes it clear where the cabin is on every floor.

• The UP/DN indicator showed which way the cabin was going.

• Protect against voltage: You can set an upper and lower limit for each phase (220V) instead Of the combined three-phase (440 V). This means the most safety.

• You can set the ampere level for each phase to ensure safety against over- and under-load.

• Phase Preventer saves electrical parts when either the single phase or the two phase power goes out.

• The Phase Sequence Corrector/Auto Phase Changer sorts out the phase polarity automatically when the phase in the source changes.

• MFFS (Magnet Floor and Final Sensing with the help of a REED sensor) is the newest version of the old limit switch technology. Reed sensors don't need to be touched to work, but their life is very long because they use detecting technology. Also, the correctness of the same can't be beat.

• A special M.C.B. was made for Rachna Elevator & Cranes to make sure there is ultimate safety in case the panel stops working.

• There is a buffer in the pit to protect the house from damage.

• Doors that fold up.

• Widest opening after the bunch.

• There is an emergency stop button on every floor that can be used to stop the ship in an emergency.

The electrical mechanical door lock means that the door won't open while the lift is moving, and it will only open on the floor where the cabin lands. The lift will not move until all of the gates are closed.

• The Over Speed Governor Stops the lift if the cabin falls free, which is done by using mechanical brakes or safety dogs. There is a counterweight with this.

Hydraulic Freight Elevator Hole Less Type is safest technology. It works in such a manner when oil push in the cylinder with the help of power pack piston moves up which rise the cabin. On another side by just releasing the wall oil from the cylinder come back in the power pack which lower down the cabin. In this system cylinder installs on the parallel of the wall. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Hydraulic Freight Elevator Hole Type is safest technology. It works in such a manner when oil push in the cylinder with the help of power pack piston moves up which rise the cabin. On another side by just releasing the wall oil from the cylinder come back in the power pack which lower down the cabin. In this system a hole is drilled in the pit where cylinder is to be install. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Freight Elevator Counter Weight Type Without Machine Room / MRL is bit expensive. In this type Geared traction machine is used in which motor is coupled to a worm which transmit the motion to the pulley / sheave through worm gear. Sheave moves the wire rope in too & fro motion who’s one end tie with the cabin & other tie with the counter weight. In this system machine is installed in the in the shaft on I-BEAM instead of machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Freight Elevator Counter Weight Type With Machine Room is bit expensive. In this type Geared traction machine is used in which motor is coupled to a worm which transmit the motion to the pulley / sheave through worm gear. Sheave moves the wire rope in too & fro motion who’s one end tie with the cabin & other tie with the counter weight. In this system machine is installed in the machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Freight Elevator Drum Type without Machine Room / MRL are very economical in the category. In this system rope winds on the drum when cabin moves upward respectively rope gets unwind from the drum when cabin moves in the downward direction. In this system machine is installed in the in the shaft on I-BEAM instead of machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

1.Freight Elevator Drum Type with Machine Room are very economical in the category. In this system rope winds on the drum when cabin moves upward respectively rope gets unwind from the drum when cabin moves in the downward direction. In this system machine is installed in the machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

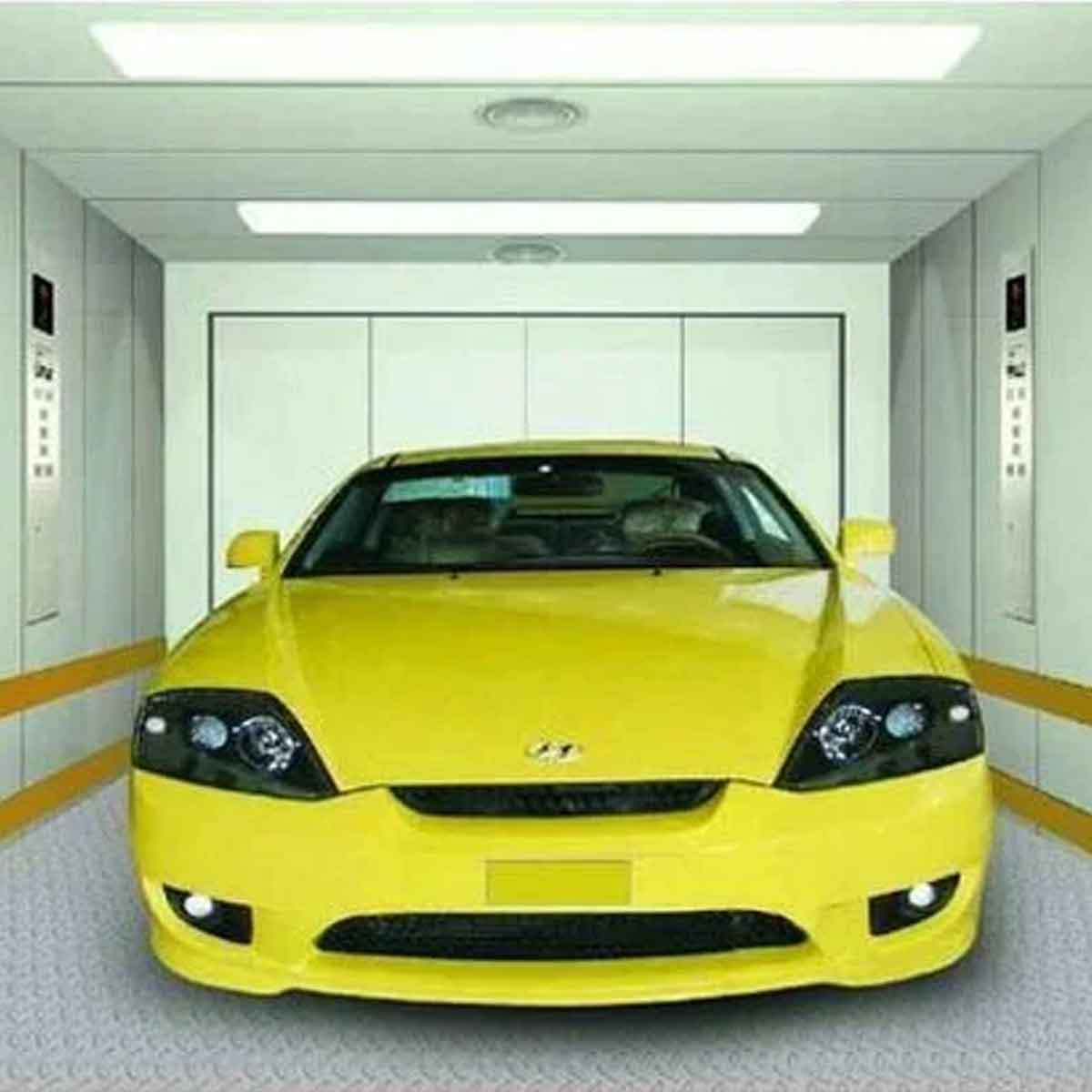

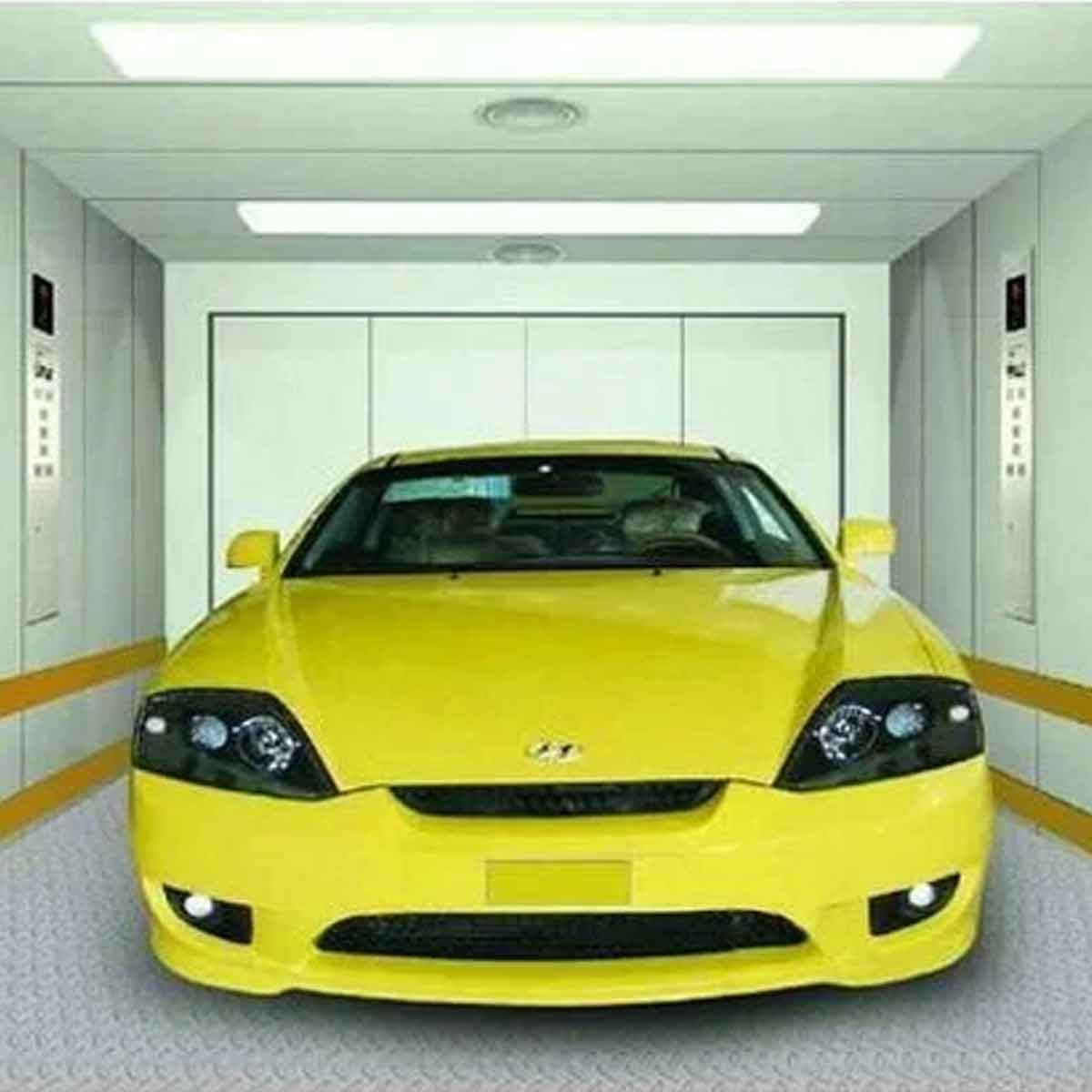

Discover the essential role of hydraulic lifts in automotive maintenance. Learn about the different types of hydraulic lifts, their mechanics, and how to choose the right one for your needs. Understand installation procedures, maintenance tips, safety practices, and future trends in hydraulic lift technology to enhance efficiency and safety in vehicle repair.

Discover the versatility and efficiency of hydraulic scissor lifts in various industries, from construction and warehousing to manufacturing and event setups. Learn about their key components, types, and crucial safety practices, as well as the latest innovations enhancing their performance and sustainability. Ensure you choose the right hydraulic scissor lift to meet your specific needs with our comprehensive guide.

Explore the various types of dumbwaiter elevators, including manual and electric models, and their applications in residential and commercial settings. Learn about the benefits, installation process, safety considerations, and future trends in dumbwaiter technology. Discover how these small freight elevators can enhance efficiency, safety, and convenience in transporting goods between floors.

Discover the essential role of freight elevators in industrial and commercial settings. Learn about their history, types, key components, safety standards, and future technological trends. From hydraulic and traction systems to modern smart elevators, find out how these robust vertical transportation systems are designed to efficiently move heavy goods and large items, enhancing operational efficiency and safety.

Discover the essential role of freight elevators in industrial and commercial settings. Learn about their history, types, key components, safety standards, and future technological trends. From hydraulic and traction systems to modern smart elevators, find out how these robust vertical transportation systems are designed to efficiently move heavy goods and large items, enhancing operational efficiency and safety.

Discover the essential role of hydraulic lifts in automotive maintenance. Learn about the different types of hydraulic lifts, their mechanics, and how to choose the right one for your needs. Understand installation procedures, maintenance tips, safety practices, and future trends in hydraulic lift technology to enhance efficiency and safety in vehicle repair.

Discover the versatility and efficiency of hydraulic scissor lifts in various industries, from construction and warehousing to manufacturing and event setups. Learn about their key components, types, and crucial safety practices, as well as the latest innovations enhancing their performance and sustainability. Ensure you choose the right hydraulic scissor lift to meet your specific needs with our comprehensive guide.

Explore the various types of dumbwaiter elevators, including manual and electric models, and their applications in residential and commercial settings. Learn about the benefits, installation process, safety considerations, and future trends in dumbwaiter technology. Discover how these small freight elevators can enhance efficiency, safety, and convenience in transporting goods between floors.

If there is no shaft to put the elevator, either inside the building or outside the building, a structure can be fabricated to put the elevator. Structure can be covered by any material (GP sheet/ Glass/fiber etc.)

100% Folding

Time Saving

Indoor

100% Folding

Time Saving

Outdoor

We provides always our best services for our clients and always try to achieve our client's trust and satisfaction.

"It's always a pleasure to work with Will and his team. RACHNA ELEVATOR & CRANES is personable, responsive, and results-oriented!"

Mr. Dayaram

HUBER SUHNER

"Always available to answer any questions. Very knowledgeable about the services they provide. Would recommend to anyone!"

Mr. Raman

KEI

"The Benefits of Installing a Hydraulic Goods Lift in Your Warehouse"

Mr. Vijay Mohan

JAGUAR