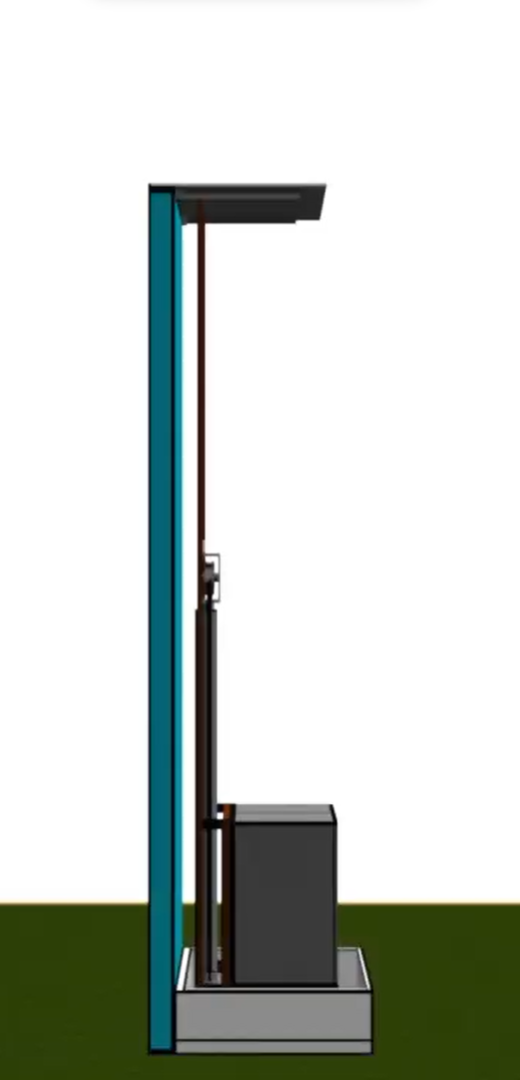

Hydraulic Car Elevator Hole Less Type is safest technology. It works in such a manner when oil push in the cylinder with the help of power pack piston moves up which rise the cabin. On another side by just releasing the wall oil from the cylinder come back in the power pack which lower down the cabin. In this system cylinder installs on the parallel of the wall. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

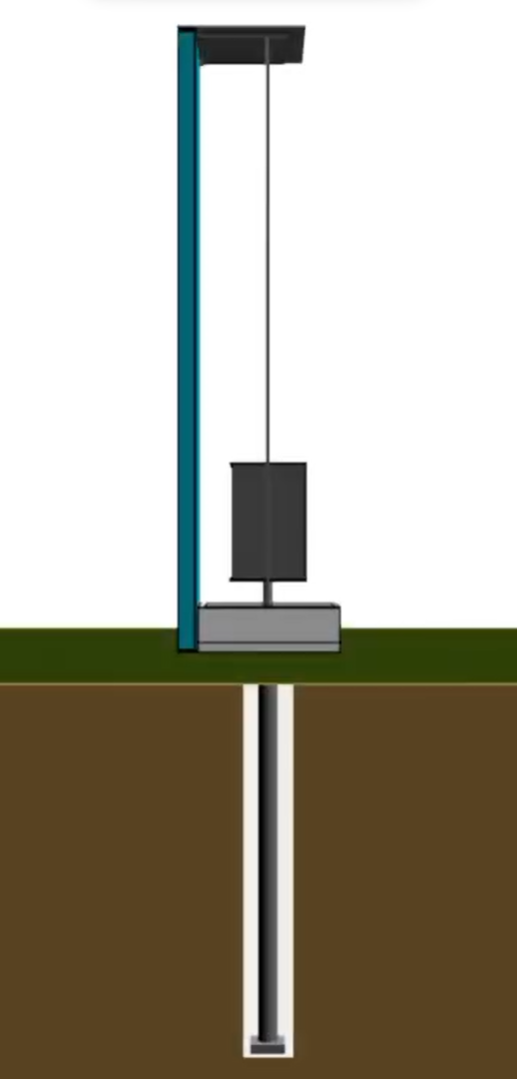

Hydraulic Car Elevator Hole Type is safest technology. It works in such a manner when oil push in the cylinder with the help of power pack piston moves up which rise the cabin. On another side by just releasing the wall oil from the cylinder come back in the power pack which lower down the cabin. In this system a hole is drilled in the pit where cylinder is to be install. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Car Elevator Counter Weight Type Without Machine Room / MRL is bit expensive. In this type Geared traction machine is used in which motor is coupled to a worm which transmit the motion to the pulley / sheave through worm gear. Sheave moves the wire rope in too & fro motion who’s one end tie with the cabin & other tie with the counter weight. In this system machine is installed in the in the shaft on I-BEAM instead of machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Car Elevator Counter Weight Type With Machine Room is bit expensive. In this type Geared traction machine is used in which motor is coupled to a worm which transmit the motion to the pulley / sheave through worm gear. Sheave moves the wire rope in too & fro motion who’s one end tie with the cabin & other tie with the counter weight. In this system machine is installed in the machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Car Elevator Drum Type without Machine Room / MRL are very economical in the category. In this system rope winds on the drum when cabin moves upward respectively rope gets unwind from the drum when cabin moves in the downward direction. In this system machine is installed in the in the shaft on I-BEAM instead of machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING

Car Elevator Drum Type with Machine Room are very economical in the category. In this system rope winds on the drum when cabin moves upward respectively rope gets unwind from the drum when cabin moves in the downward direction. In this system machine is installed in the machine room. Advantage: -

IF THERE IS NO SHAFT TO PUT ELEVAOR, STRUCTURE CAN BE FABRICATED TO PUT THE ELEVATOR. STRUCTURE CAN BE COVERED BY ANY MATERIAL (GP SHEET / GLASS / FIBER / WIRE MASH e.t.c.). ADVANTAGES:

INDOOR STRUCTURE: INSIDE THE BUILDING

OUTDOOR STRUCTURE: OUTSIDE THE BUILDING